From the spindle to the device: grinding technique that fits

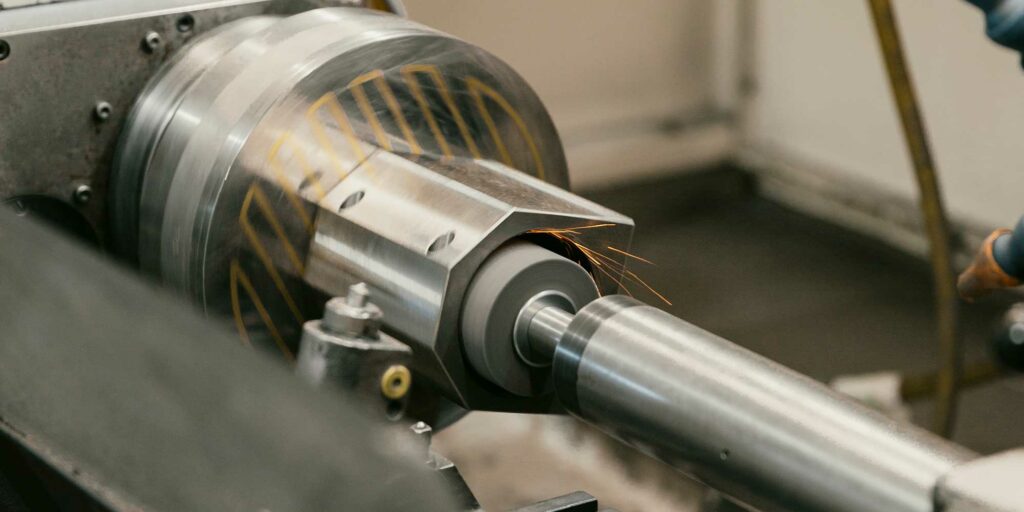

What grinding technology does – and why it is crucial

or complex radii. spindles ensure the controlled rotation of the tool, while Breaking systems hold the grinding wheel to size and profile. This technique is crucial for functional and aesthetic end results – whether in implants, bearing housings or highly stressed machine parts.

What our Grinding spindles you are designed so that they can be integrated exactly into your machine – whether retrofit or new development. Compact, powerful and precisely tailored to your requirements.

Our product portfolio in grinding technology

Steinmetz grinding technology gives you a wide range of high quality Grinding spindles – from standard solutions to individual custom productions. Our spindles are characterized by low-maintenance grease lubrication, high stiffness, precise tool mounts and durable construction. Discover our options at a glance:

Our Belt-driven grinding spindles convince with high speeds, robust design and reliable, force-locking tool mount. Available in different diameters and lengths, they cover a wide range of applications – from classic external machining to high precision internal grinding solution. Variants with HSK recording are also available for automated processes. Thanks to proven fat burning or oil air lubrication, they work particularly low maintenance.

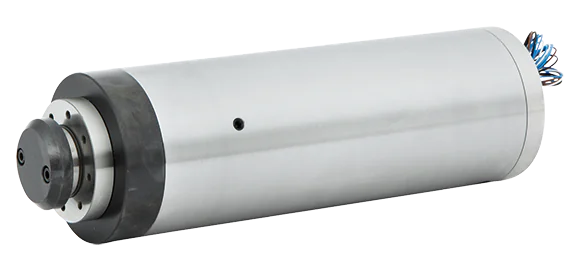

Our Motor spindles unite drive and spindle in a compact, powerful unit. They are ideal for series processes where the highest torques and process stability are required. In addition to versions with a smooth tool mount, we offer HSK variants for automated production cells. Water cooling, grease duration lubrication, oil air lubrication and high stiffness values ensure a long service life in continuous use.

Our Internal grinding spindles are specially designed for sensitive interior processing – compact, precise and powerful. The ceramic-mounted belt-driven variants offer maximum speeds and low tolerances, ideal for applications in medical technology, tool construction or turbine grinding. Also available as motor spindles with collet device – for example for grinding optics lenses.

For External circular grinding we offer robust, high-performance spindles with different interfaces – from classic glazed mount to HSK design. The belt-driven variants allow high speeds and precise tool tension. Motor-assisted versions deliver constant performance with maximum stiffness – even in long grinding cycles. Each spindle is designed for stability, smooth running and process reliability.

Special productions

Not every application can be covered with standard spindles – so we develop individual special solutions exactly according to your requirements. Whether extremely long spindles for turbine housing, special receptacles for pot grinding wheels or high-speed spindles for machining aluminum rims: We implement customized solutions with proven technology. All special designs are equipped with right-hand/left-hand drive, grease lubrication or oil-air lubrication and precise tool holder. Together with you we find the optimal spindle solution for your machine and your process.

Other grinding devices

In addition to our standard portfolio, we offer further special devices for individual grinding tasks. Whether special holders, test mandrels or complex structures – we develop functional solutions precisely tailored to your machine and process.

We also offer solutions dressing technologyas Cycle breakers, Diamond roller dressing equipment and more. You can find them here. (Link to overview Abrichttechnik)

Grinding technology: The heart of your grinding processes

Our grinding technology ensures the necessary precision in the process – regardless of whether it is a new machine or retrofit. We develop, manufacture and Repair spindles, Holder and dressing technology exactly tailored to your requirements. Circular accuracy below 2 μm, thermally stable housings and durable constructions form the basis for repeatable results – even in continuous operation.

Advantages of our grinding technology

Exact rounding accuracy

Thermically stable design

Maintenance-free operation

Maximum compatibility

Low vibration design

Longevity also in 3-layer operation

Here our grinding technique is used

Our grinding technology is used where reliable dimensional accuracy, high surface quality and trouble-free processes are important – precisely where standard solutions are not sufficient.

- Tool and mold construction: grinding processes for complex contours, high surface qualities and closest tolerances for tools and mold inserts.

- Automotive industry: Precise processing of safety-critical components such as crankshafts, bearings or injection systems – reliable in the process even at high volumes.

- Medical technology: treatment of medical components with micrometer-precise dimensional accuracy, for example implants, surgical instruments or prosthesis components.

- Machine and plant construction: Precise grinding results on structural and functional parts, often in small numbers and with changing requirements.

- machining and wage production: Flexible integration into existing manufacturing processes, short setup times and reliable repeatability in changing orders

Our services around your grinding technology

- Consulting & Construction: We examine your technical requirements in detail and develop practical solutions – precisely tailored to your machine, your tolerances and your everyday production.

- Customized productions: Whether small series or single piece – we manufacture customized spindles, devices or special holders exactly according to drawing, CAD data or pattern specifications.

- Spindle repair: We repair grinding wheeland Breaking spindles all common factory products – fast, precise and with original or precise spare parts. Often within few business days.

- Spare parts: Many standard components are available from stock. For special parts we ensure short delivery times – so that your production remains predictable and failures are avoided.