Spindle technology of Steinmetz grinding technology

Our portfolio for spindle technology

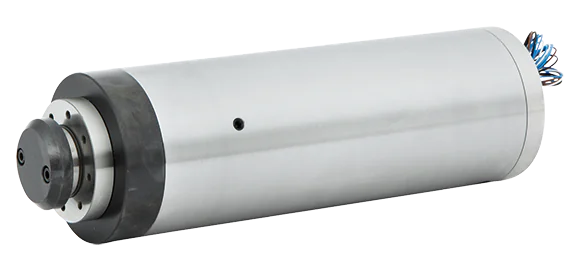

Compact drive unit with high power density – ideal for lack of space. Motor spindles are preferably used in modern production lines in which dynamics, precision and integrated control are required.

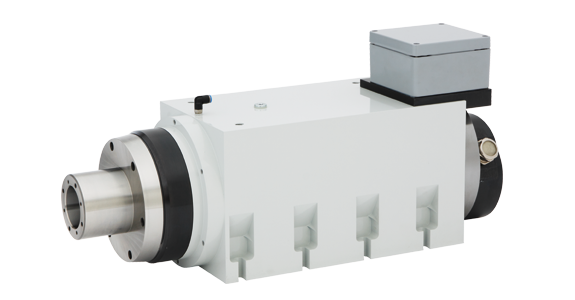

This type of spindle is particularly versatile and is driven via an external drive. It is ideally suited for flexible machine concepts or as a cost-efficient solution RetrofitProjects.

Our spindle technology is used here

Our spindles perform critical tasks in many industries: They drive tools, ensure precise movements and enable finest machining results – with consistently high repeatability. In each industry, they meet specific requirements, from maximum dimensional accuracy to reliable continuous load in series operation.

- Tool and mold construction: An exact shape is decisive here. Our spindles allow the grinding of complex contours with high dimensional accuracy.

- Automotive and aircraft industry: In safety-critical components, tolerances must be adhered to and high preliminary wear must be driven. Our spindles secure this permanently.

- Medical technology: Medical components require micrometer-precise surfaces. Our spindles deliver low vibration and reproducible results.

- Mechanical engineering: Whether individual parts or series – our spindles ensure consistent quality with different materials and machining strategies.

- machining and wage production: Fast changing orders require adaptability. Our dimensions

Customised spindles – according to your needs

We manufacture spindles exactly according to your technical specifications. These include specific dimensions, adapted bearing concepts, individual flange or connection types as well as the integration of sensor systems or drive systems. We also offer constructively suitable new developments for machines with limited installation space or with missing spare parts availability.

Each special solution is implemented on the basis of your drawings, measurement data or machine specifications – for a 100% compatibility and direct usability.

Our services – concrete, reliable and solution-oriented

- Technical advice with feasibility analysis: We examine your requirements in detail and provide you with a reliable assessment of technical feasibility.

- Individual special solutions: Whether Retrofit, new development or single piece – we design and manufacture spindles exactly according to your specifications.

- Repair all common grinding spindles: We repair your grinding spindles regardless of brand – fast, precise and with original or equivalent spare parts.

- Spare parts supply within 24–48 hours: Many common spare parts are in stock with us. This minimizes downtime and keeps your production running.