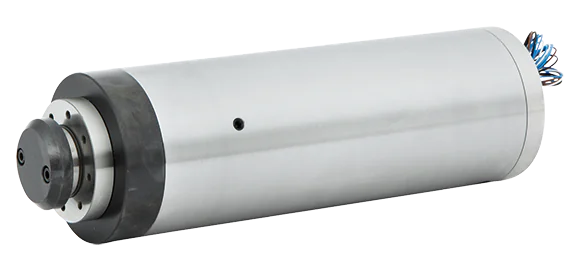

grinding spindle of Steinmetz grinding technique

The heart of the grinding machine: The grinding spindle

The grinding spindle is the central component when it comes to precise and repeatable grinding processes. It transmits the drive force to the grinding tool in a controlled manner and ensures that each revolution is exactly seated. The decisive factor is not only the speed, but above all the smooth running, the thermal stability and the absolute accuracy of the round running – with us below 2 μm.

What makes our grinding spindles special: they are designed to be integrated exactly into your machine – whether retrofit or new development. Compact, powerful and precisely tailored to your requirements.

Portfolio: Our grinding spindles in detail

Whether precise internal machining, powerful external machining or highly automated series processes – our grinding spindles offer the right solution for a wide range of applications. Each spindle is a robustly designed system of optimal tool mount, long-lasting storage and low-maintenance lubrication designed for maximum performance and process reliability.

Our Belt-driven grinding spindles offer high speeds, reliable power transmission and flexible installation options – ideal for classic grinding machines and modern production cells. They are low-maintenance thanks to fat burning and available in numerous designs.

With smooth tool holder

Power-locking connection, high concentricity accuracy and robust design for external machining.

- Speed: up to 20,000 min-1

- stiffness radial: 135,2–310,2 N/μm

- stiffness axial: 67,6–155,1 N/μm

- Ø60–120 mm, different lengths available

- Lubrication: grease duration lubrication

With HSK recording

Quick change, high precision – ideal for automated processes.

- Speed: up to 18,000 min-1

- HSK-C40 to HSK-C63

- stiffness radial: up to 421.8 N/μm

- stiffness axial: up to 254.3 N/μm

Special solutions

Individual adaptation of geometry, speed and interface – for example for rims, spark plugs or glass processing.

Our Motor spindles Drive and spindle unite in a compact, powerful unit – ideal for series processes, high torques and tight installation spaces. Through integrated water cooling and grease duration lubrication, they achieve a long service life with minimal maintenance effort.

With smooth tool holder

For classic grinding applications with reliable tool tension.

- Speed: up to 3,000 min-1

- Power: up to 5.5 kW

- stiffness radial: up to 310.2 N/μm

- stiffness axial: up to 155.1 N/μm

- Lubrication: grease duration lubrication

With HSK recording

Perfect for automated systems – short setup times, high change accuracy.

- HSK-C40 to C63

- Speed: up to 3,000 min-1

- stiffness radial: up to 421.8 N/μm

- stiffness axial: up to 254.3 N/μm

- Water cooling standard

Designed specifically for internal grinding: Our Internal grinding spindles convince with compact design, precise ceramic bearings and high speeds – ideal for applications with tight installation conditions and highest tolerance requirements.

- Speed: up to 29.000 min-1

- Ø60–120 mm, length up to 1200 mm

- stiffness radial: up to 380.2 N/μm

- stiffness axial: up to 76.4 N/μm

- Ceramic spindle bearings, grease duration lubrication

For classic outer round machining with high load and best results for round running and surface quality.

- Variants: belt transmissions or motorized

- Tool holder: conical or HSK

- stiffness radial: up to 421.8 N/μm

- Speed: up to 22,000 min-1

- special solutions for grinding glass screens or large-volume workpieces

Where our grinding spindles are used

Whether fine grinding in mold construction or solid gas in series production – our grinding spindles prove their strength where every micrometer deviation counts among others:

- Tool and mold construction: for exact contours and repeatability

- Serial production: especially at high quantities and tight tolerances

- Machine modernization (retrofit): to optimize existing systems

- Wage production: if flexibility and quality are required

How to benefit from our grinding spindles

Measurable precision

Our grinding spindles achieve a circular accuracy of less than 2 μm. This keeps the tool path constant – regardless of speed, temperature or machining time.

Efficient rest

The specially adapted bearing technology reduces vibrations and minimizes unbalances during operation. This not only extends the service life of your tools, but also significantly improves the grinding quality – especially with sensitive materials or tight tolerances.

Space-saving design

Thanks to its slim design, our grinding spindles can also be used where standard solutions reach their limits. Ideal for retrofit projects or compact machine concepts where every millimeter counts.

Flexible cooling and lubrication

We offer air, water or oil fog lubrication tailored to your thermal and process requirements. This ensures constant operating temperatures, protects the bearings and increases the overall life of your spindle.

Long-lived design

Our grinding spindles are designed for long-term use under high load. Robust components, coordinated sealing systems and precise production guarantee low-maintenance operation – even in 3-layer operation.

Customizable integration

Whether special flange geometry, installation dimensions or tool holder – we adapt each spindle exactly to your requirements. Even in small quantities, we realize special solutions that seamlessly fit into your machine.

We offer you this at Steinmetz Schleiftechnik

Technical advice at eye level

Our spindle technicians speak your language. Together we find the optimal solution – fast, direct and practical.

Dimensional design

We examine feasibility and develop exactly what your process needs. No compromises, no standards of the bar.

Reaction times which act

Offers are available within 24 hours. We also deliver spare parts and repairs within 24–48 hours in case of service.

Individual production

Whether single piece or small series – we realize custom productions flexibly. We integrate sensor technology, cooling or special geometries exactly according to your requirements.

Find the right grinding spindle now – or request individual solution!

Whether you are a compact grinding spindle for cramped installation conditions, a high-performance model for continuous use or customized custom production – in the case of Steinmetz grinding technology you will find exactly the solution that fits your application.