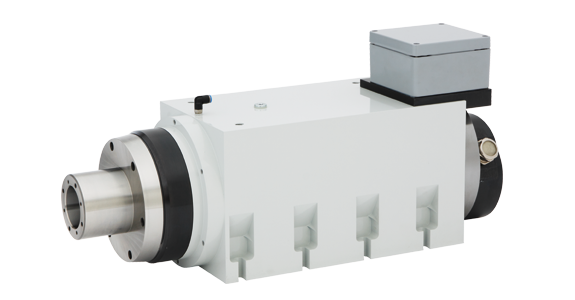

Our inner grinding spindle – precision that is in every detail

Our inner grinding spindles bring your grinding processes to the point – with uneven precision and stability. They also master the most complex tasks in which conventional solutions fail. Perfect for every challenge – if every millisecond and every micrometer deviation counts.

Internal grinding spindle: You need to know

An inner grinding spindle is the precise centerpiece of each grinding machine, which is responsible for the exact internal grinding of workpieces. It ensures that the grinding tool meets the workpiece with absolute accuracy and processes it in narrow, difficult to access areas – without compromises in precision. Thanks to its refined storage and perfect geometry, it rotates almost freely from vibrations and deviations.

This finely tuned Technology allows constant processing quality, even under the most demanding conditions. In industries where even the smallest errors make the difference, the inner grinding spindle guarantees perfect results in which any tolerance is exactly maintained.

Inner grinding spindle of Steinmetz

Our belt-driven inner grinding spindle with smooth tool holder offers exceptional precision and performance for demanding grinding processes. The combination of high-quality grease duration lubrication and ceramic spindle bearing ensures a long service life and high stability – even at high speeds. It is perfect for use in confined installation spaces and is the ideal solution for precise internal grinding.

Technical data

- Diameter A: 60–120 mm (depending on model)

- Length B: 200–500 mm (depending on model)

- Maximum speed: 12,000 – 29.000 min-1

- stiffness radial: 165.6 N/μm – 380.2 N/μm (depending on model)

- stiffness axial: 33.3 N/μm – 76.4 N/μm (depending on model)

The key to fault-free grinding processes

You wonder why choosing the right inner grinding spindle is so important? Very simple: your production depends on the precision. A faulty spindle quickly leads to inaccurate machining and increased machine shutdowns.

Our inner grinding spindles guarantee constant results, maximum efficiency and a long service life, even with highest requirements. This precision is crucial in medical technology or in mould construction where every micrometer deviation counts.

Advantages of the inner grinding spindle

Maximum precision

Our inner grinding spindles guarantee a round running accuracy of less than 2 μm. This exceptional precision ensures that each workpiece is processed within the narrowest tolerances, ensuring the quality of your products at a constant high level and reducing rework or reject to a minimum.

High speeds

With our spindles you achieve high speeds that speed up your grinding processes without impairing accuracy. This means less time spent in production without cutting off quality – ideal for fast and efficient production.

Low maintenance costs

Our internal grinding spindles are designed for a long service life in continuous operation. Robust materials, sophisticated storage technology and long-lasting lubrication systems significantly reduce maintenance requirements and ensure that your machines run reliably and without frequent downtime.

Easy integration

Whether new construction or Retrofit – our compact inner grinding spindles can be easily integrated into your existing machine environment. This flexibility ensures that you do not have to compromise performance and that your production lines can easily switch to the latest technology.

Advantages of the inner grinding spindle

Individual advice

We do not have standard solutions. We listen carefully, understand your requirements and provide tailor-made solutions that are perfectly suited to your specific needs. Our team of experts will help you find the optimal inner grinding spindle for your application.

Tailored production

We do not have standard solutions. We listen carefully, understand your requirements and provide tailor-made solutions that are perfectly suited to your specific needs. Our team of experts will help you find the optimal inner grinding spindle for your application.

Speed that counts

We know how important fast reaction times are. You will receive offers within 24 hours and spare parts in only 24–48 hours to minimize downtime and continue your production without interruption.

Find the right inner grinding spindle now – or request individual solution!

You need an inner grinding spindle for your grinding machine or plan a retrofit project? We develop and deliver a solution that fits – technically and economically.