Radia Breaker – Exact radii profiles for maximum process reliability

When it comes to exact radii profiles, a standarddressing device fast at the limit. Our radii dressing device has been specially designed to shape convex and concave grinding wheel geometries precisely, reproducible and stable in internal and external grinding – with a transverse shape deviation of maximal ±1 μm.

What do radii dressing devices – and when do you need them?

Radia dressing equipment are used wherever grinding wheels are to receive exact, reproducible radii profiles – for example for tools, fit surfaces or shape contours with high quality standards. They enable the targeted alignment of concave and convex radii and thus ensure constant grinding results, narrow tolerances and smooth surfaces.

In contrast to standard solutions, they are specially designed for swivelling – with play-free mounting, driven radius axis and variable tool mounting. Whether single-grain diamond or rotating diamond roller: radii dressing devices are a central component for stable grinding processes in complex profile requirements.

Our radii dressing equipment at a glance

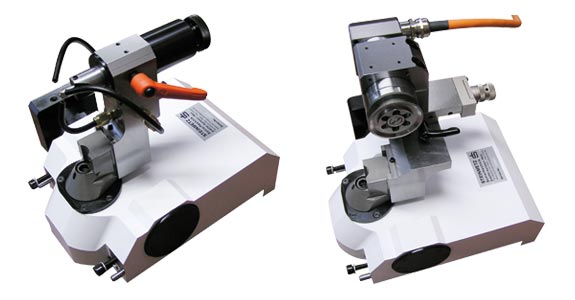

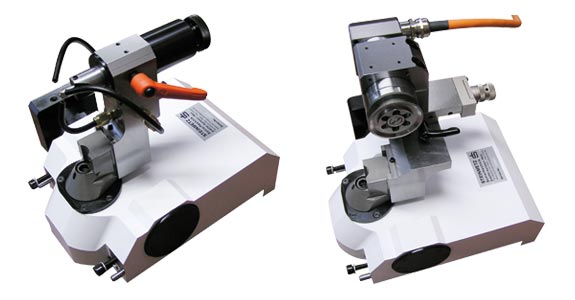

Radiating device RAS-400×175

The RAS-400×175 radii dresser has been specially designed for precise alignment convex and concave radii developed on external circular grinding machines. It is mounted directly on the machine table and is mounted on both sides with high accuracy – ideal for use with high timing. The radius movement takes place via a servomotor with play-free harmic drive transmission. The diamond roller is driven by the proven dressing spindle AS58x94F/025. Alternatively, the system can also be used with a single grain diamond.

Technical data:

- Maximum adjustable radius: R = 20 mm

- Largest grinding wheel Ø: 400 mm

- dressing spindle AS58x94F/025

- Diamond roller mount Ø: 20h2 mm

- Diamond rollers clamping width: 10 mm

- Diamond rolls outer Ø: 60 mm

- Speed of fat burning: max. 22000 min-1

Radiating device RAS-610-R65

The RAS-610-R65 is specialized in precise alignment of concave radii and is ideal for large grinding wheels up to Ø 610 mm. The radius movement takes place via a servo drive with non-playing harmonic drive transmission. The feed of the individual grain diamond is controlled and pneumatically clamped by a stepping motor. The system is designed for maximum accuracy, high repeatability and reliable operation in daily series.

Technical data:

- grinding wheel Ø 610

- R max. = 65 (concav)

- Single grain diamond: Ø 8 x 35

RAS-125-01 Radiator

The RAS-125-01 is a compact, fly-mounted radii dressing device for precise individual grain alignments. It is designed for grinding wheels up to Ø 120 mm and radii up to R = 25 mm. The pivoting movement of the dressing arm is effected hydraulically, the radius movement takes over a servo drive with harmonic drive transmission. After alignment, the system automatically returns to the rest position – ideal for applications with a clear clock structure and limited installation space.

Technical data:

- Maximum adjustable radius: R = 25 mm

- Largest grinding wheel Ø: 120 mm

- single cornealing diamond: Ø 8 x 35, 1 carat

RAS-118-01 Radiator

The RAS-118-01 has been developed specifically for use in internal circular grinding machines with narrow installation spaces. Equipped with a dressing spindle AS58x94F/025, it is suitable for grinding wheels up to Ø 120 mm and radii up to R=25 mm. The pivoting movement takes place hydraulically, the radius movement is carried out by means of a compact direct-current transmission motor with reduction. After alignment, the arm automatically returns to the rest position – ideal for confined spaces and repeatable profiles.

Technical data:

- Maximum adjustable radius: R = 25 mm

- Largest grinding wheel Ø: 120 mm

- dressing spindle AS58x94F/025

- Diamond roller mount Ø: 20h2 mm

- Diamond rollers clamping width: 10 mm

- Diamond rolls outer Ø: 60 mm

- Speed of fat burning: max. 22000 min-1

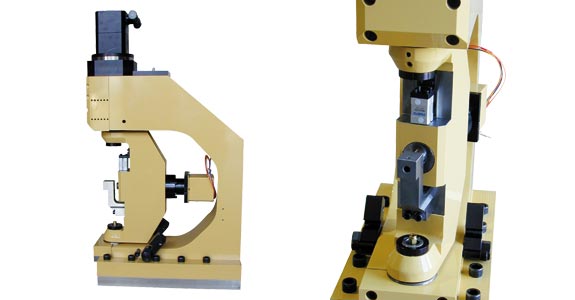

Radiating device ABV-320F/001

The ABV-320F/001 is a flyingly mounted dressing device for circular grinding machines, designed for convex and concave radii Wheels to Ø 500 mm. The radius movement takes place via a servo drive with a screw gear that can be adjusted without play. By default, single-grain diamond is executed; alternatively, Diamond roller are used – driven by dressing spindle AS58x94F/026. The device convinces with flexibility, stable guidance and high repeatability with varying disc diameters.

Technical data:

- grinding wheels Ø: 400 mm; radius concave max. 30 mm; radius convex max. 20 mm

- grinding wheels Ø: 500 mm; radius concave max. 30 mm; radius convex max. 10 mm

- Single cornealing diamond: Ø 9.52 mm x 35 mm

- Top height: 225 mm

These advantages offer a radii dressing device

Highest profile accuracy

Customizable

Maintenance-free continuous operation

Thermically stable and durable

Typical applications

Our radii dressing devices are used wherever the highest profile accuracy, repeatability and reliable integration are required in existing processes:

- Tool and mold construction: aligning complex radii contours with high dimensional accuracy

- Automobile industry: series production with narrow tolerances and high cycle number

- Aviation industry: Precise profiling of safety-relevant components

- Medical technology: Form-precise grinding profiles for micromechanical components

- machining and contract production: Flexible alignment with changing workpiece geometries

- Mechanical engineering: Integration in new machines for stable and repeatable grinding processes

- Retrofit and plant modernization: retrofitting in existing grinding machines with limited installation space

- Bearing Technology and Roller Bearing Grips: Radiation Processing for Uniform Tracks and Fits

- Hydraulic components: Precise alignment of sealing and control surfaces

- Precision mechanics and optics: production of finest grinding radii with maximum surface quality