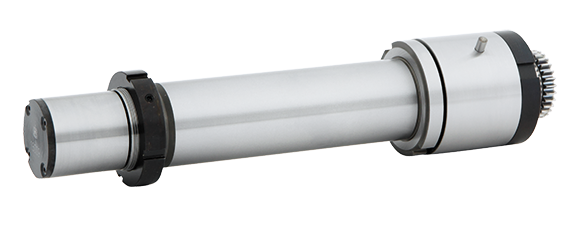

for various diamond roller dressing units

Smooth running is very important when truing a grinding wheel using a diamond roll. Our mandrels for diamond rolls comply with this requirement. A special design and highest precision of the bearings incorporated guarantee optimum results. They mandrels are adapted to suit our truing devices with diamond rolls.

Mandrels for diamond rolls are produced in ultra-high precision. Radial run-out and axial run-out of the mandrel for the diamond roll are specified with a tolerance of 0.002 mm in radial and axial direction and thus ensure essential conditions for optimum and economic truing operations using a diamond roll.

The OD of the mandrel of the diamond roll should be chosen as big as possible in order to ensure the maximum stiffness required.

Mandrels for diamond rolls, used for diamond roll truing devices, are either grease-lubricated for life or oil-mist lubricated. The sense of rotation, either clockwise or anticlockwise, may be selected as required.

For a quick change of the diamond roll, the complete set of diamond roll on its mandrel is provided. Maximum radial run-out and axial run-out of the mandrel for the diamond roll amount to a maximum of 2 μm.

For every diamond roll a diamond roll mandrel should be provided. When exchanging the complete unit of mandrel and diamond roll the following advantages result: The supplier of the diamond roll may mount the diamond roll on the mandrel, thus optimizing radial run-out and side run-out.

Furthermore

- Quick changing of diamond roll with mandrel

- Low wear of diamond roll mandrel

- Low wear of diamond roll

- Better results for truing operation

Diamond Roller Dressing Arbors

Grease lubrication

=> A plan can be displayed and downloaded by clicking on the product names on the left side of the table (each as a PDF file – opens in a new window):

| Designation | Ø A mm | B mm | Ø C

mm | D

mm | Ø E mm | F

mm | Ø G mm | H

mm | I

mm | J

mm | K

mm | Ø L

mm | M

mm | Speed RPM max. |

| STR52x50F/006 | 52 | 50 | 80 | 64 | 48 | 50 | 24 | 30 | 13 | 15 | 40 | 6 | 226,5 | 4500 |

| STR52x100F/003 | 52 | 100 | 80 | 64 | 48 | 50 | 24 | 30 | 13 | 15 | 40 | 6 | 276,5 | 4500 |

| STR52x150F/003 | 52 | 150 | 80 | 64 | 48 | 50 | 24 | 30 | 13 | 15 | 40 | 6 | 326,5 | 4500 |

| STR52x200F/006 | 52 | 200 | 80 | 64 | 48 | 50 | 24 | 30 | 13 | 15 | 40 | 6 | 376,5 | 4500 |

| STR56x50F/006 | 56 | 50 | 80 | 64 | 48 | 50 | 24 | 30 | 13 | 15 | 40 | 6 | 226,5 | 4500 |

| STR56x100F/003 | 56 | 100 | 80 | 64 | 48 | 50 | 24 | 30 | 13 | 15 | 40 | 6 | 276,5 | 4500 |

| STR56x150F/003 | 56 | 150 | 80 | 64 | 48 | 50 | 24 | 30 | 13 | 15 | 40 | 6 | 326,5 | 4500 |

| STR56x200F/006 | 56 | 200 | 80 | 64 | 48 | 50 | 24 | 30 | 13 | 15 | 40 | 6 | 376,5 | 4500 |

| STR63x50F/006 | 63 | 50 | 80 | 64 | 60 | 60 | 24 | 30 | 13 | 15 | 40 | 6 | 237 | 4500 |

| STR63x100F/006 | 63 | 100 | 80 | 64 | 60 | 60 | 24 | 30 | 13 | 15 | 40 | 6 | 287 | 4500 |

| STR63x150F/001 | 63 | 150 | 80 | 64 | 60 | 60 | 24 | 30 | 13 | 15 | 40 | 6 | 337 | 4500 |

| STR63x200F/005 | 63 | 200 | 80 | 64 | 60 | 60 | 24 | 30 | 13 | 15 | 40 | 6 | 387 | 4500 |

| STR80x100F/003 | 80 | 100 | 100 | 78 | 75 | 62 | 25 | 40 | 13 | 18 | 55 | 6 | 316 | 4300 |

| STR80x150F/003 | 80 | 150 | 100 | 78 | 75 | 62 | 25 | 40 | 13 | 18 | 55 | 6 | 366 | 4300 |

| STR80x200F/003 | 80 | 200 | 100 | 78 | 75 | 62 | 25 | 40 | 13 | 18 | 55 | 6 | 416 | 4300 |

| STR80x300F/003 | 80 | 300 | 100 | 78 | 75 | 62 | 25 | 40 | 13 | 18 | 55 | 6 | 516 | 4300 |

| STR100x400F/001 | 100 | 400 | 140 | 132 | 95 | 105 | 55 | 80 | 20 | 20 | 90 | 8 | 764 | 3000 |

=> A plan can be displayed and downloaded by clicking on the product names on the left side of the table (each as a PDF file – opens in a new window):

| Designation | Ø A

mm | B

mm | Ø C

mm | D

mm | Ø E

mm | F

mm | H

mm | I

mm | J

mm | K

mm | Ø L

mm | M

mm | Speed RPM max. |

| STNO52x40F | 52 | 40 | 46 | 16 | 46 | 21 | 11 | 4 | 11 | 8 | 4 | 106 | 4500 |

| STNO52x42F | 52 | 42 | 46 | 19 | 46 | 21 | 10 | 4 | 9 | 8,5 | 4 | 109 | 4500 |

| STNO52x49F | 52 | 46 | 46 | 17 | 46 | 21 | 10 | 3,5 | 10 | 8,5 | 4 | 115 | 4500 |

| STNO52x56F | 52 | 56 | 46 | 12 | 46 | 21 | 11 | 4 | 9 | 8 | 4 | 116 | 4500 |

| STNO52x62F/001 | 52 | 62 | 46 | 18 | 46 | 23 | 18 | 4 | 9 | 8,5 | 4 | 136 | 4500 |

| STNO55X80F/001 | 55 | 80 | 46 | 18 | 46 | 23 | 18 | 4 | 8 | 8,5 | 4 | 154 | 4500 |

| STNO63X42F | 63 | 42 | 46 | 18 | 46 | 23 | 11 | 4 | 8 | 8,5 | 4 | 109 | 4300 |

| STNO63X56F/001 | 63 | 56 | 46 | 13 | 46 | 21 | 11 | 4 | 9 | 8 | 4 | 116 | 4300 |

Diamond Roller Dressing Arbors

Oil mist lubrication

=> A plan can be displayed and downloaded by clicking on the product names on the left side of the table (each as a PDF file – opens in a new window):

| Designation | Ø A

mm | B mm | C

mm | D mm | E mm | Ø F mm | G mm | H mm | J mm | M

mm | Speed RPM max. |

| RD52x130Ö/005 | 52 | 130 | 72 | 62 | 110 | 212 | 20 | 92 | 20 | 230,288 | 4500 |

| RD52x170Ö/005 | 52 | 170 | 72 | 62 | 110 | 252 | 20 | 92 | 20 | 270,288 | 4500 |

| RD52x280Ö/005 | 52 | 280 | 72 | 62 | 110 | 363 | 20 | 92 | 21 | 381,288 | 4500 |

| RD56x120Ö/001 | 56 | 120 | 72 | 72 | 110 | 212 | 20 | 92 | 20 | 230,288 | 4500 |

| RD56x130Ö/001 | 56 | 130 | 72 | 62 | 110 | 212 | 20 | 92 | 20 | 230,288 | 4500 |

| RD56x170Ö/001 | 56 | 170 | 72 | 62 | 110 | 252 | 20 | 92 | 20 | 270,288 | 4500 |

| RD56x280Ö/001 | 56 | 280 | 72 | 62 | 110 | 363 | 20 | 92 | 21 | 381,288 | 4500 |

| RD65x180Ö | 65 | 180 | 80 | 14 | 110 | 212 | 20 | 92 | 18 | 230,288 | 4500 |

| RD65x220Ö | 65 | 220 | 80 | 14 | 110 | 252 | 20 | 92 | 18 | 270,288 | 4500 |

| RD65x330Ö | 65 | 330 | 80 | 14 | 110 | 363 | 20 | 92 | 19 | 381,288 | 4500 |