Spindles of stone mesh

Our spindles: An overview

We do not manufacture our rotary spindles according to the catalog, but according to your reality: construction space, workpiece, machine, production target. With these four core categories we meet a wide range of requirements:

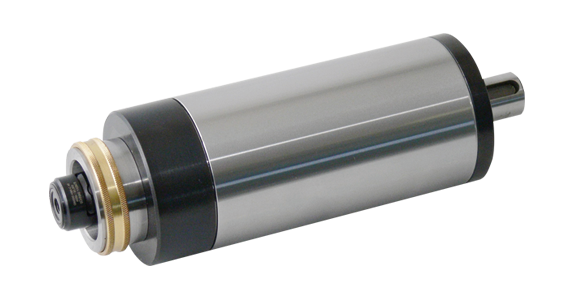

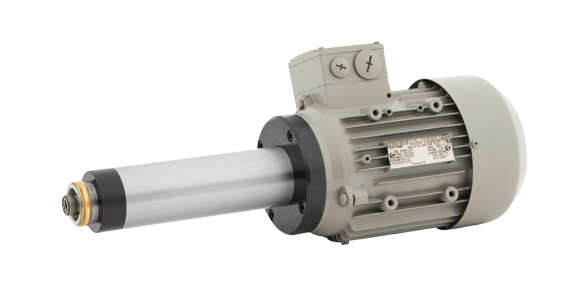

Compact drive unit with high power density – ideal for lack of space. Motor spindles are preferably used in modern production lines in which dynamics, precision and integrated control are required. Our motor spindles provide maximum reliability with easy integration and minimal maintenance, thanks to integrated water cooling and long-lasting grease lubrication.

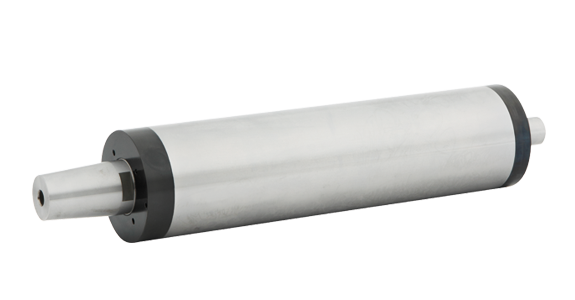

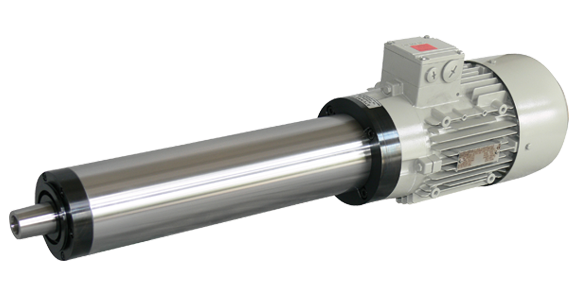

This type of spindle is particularly versatile and is driven via an external drive. It is ideally suited for flexible machine concepts or as a cost-efficient solution RetrofitProjects. Thanks to its robust design and the possibility for individual adjustment with regard to tool mounting, mounting and installation dimensions, they offer maximum freedom in planning and implementation.

Special solutions – individual, fit, uncompromising

If Standard doesn’t fit, we’ll be customized. Whether space limitation, unusual tool mounts, sensor integration or exotic materials – we develop and produce the right rotary spindle exactly according to your requirements.

Product advantages of our rotary spindles

Our rotary spindles were not built for the showroom, but for the workshop. They work where it goes rough, hot, tight and fast. What makes our spindles special:

Circular accuracy < 2 μm

Micrometer precision – from the first to the last workpiece. Our precisely aligned, pre-stressed high-precision bearings ensure that the tool run remains exactly – even under thermal stress and after many operating hours.

Thermically stable in continuous operation

Our spindles don’t move after hours. The combination of rigid housing material, optimized heat dissipation (e.g. by water cooling) and controlled lubrication prevents drift and dimensional migration – particularly important in multilayer operation.

Low-maintenance design

Our spindles are standard equipped with grease duration lubrication. This eliminates regular relubrication – reducing downtime and saving time. In high-performance applications, we use oil-air lubrication – always matched to your profile.

Custom integration

Whether special flange geometry, HSK or conical tool mount, sensor technology or connection to existing interfaces – we deliver solutions that fit your machine. Also in the case of narrowest construction spaces or retrofit projects.

Longevity – even with high load

We’re constructing for practice. Our spindles run reliably under load, even in three-layer operation. Robust sealing systems, high-quality bearings and precise components ensure a service life that is paid.

Our services – beyond the spindle

In Steinmetz grinding technique, the power does not end with the delivery of the spindle. We accompany you technically, strategically and in case of emergency – with the following services:

Technical advice at eye level

With us you can talk directly with an experienced spindle technician, not with sales. Together we analyze your needs – from building space issues to material topics. Result: a feasible, practice-proven recommendation within a short time.

Individual design & manufacturing

You have a drawing? Or just a building room? We put out, check feasibility, construct and manufacture exactly what your machine needs – even in small series or as a single piece. Without a long wait.

Whether your own or strange spindle: We repair professionally – with original or equivalent components. Our goal: to make your machine productive as soon as possible.

Spare parts and offers in 24–48 hours

Short paths, flat hierarchies and a well-stocked warehouse ensure that you do not have to wait. You will receive your offer within a working day. We usually deliver spare parts within 24 to 48 hours.

You need a spindle that fits exactly?

You have a drawing, an idea or just a concrete problem in your machine? Then talk to us. We provide you with a well-founded offer within 24 hours – and if necessary within a few days the appropriate spindle.