Steinmetz outer grinding spindle – When each revolution counts

Each rounding counts: Our external grinding spindles ensure measurable precision, stable processes and long service life – even with high load. Whether series production or special solution: we supply spindles that convince from the first revolution.

External grinding spindle – key component for precise external grinding

The outer grinding spindle is more than just one drive: It is the central element when it comes to dimensional accuracy, surface quality and process reliability during external grinding. Its task is to rotate the grinding tool absolutely without play and low vibration – even at high speeds and continuous load.

In contrast to Internal grinding spindle works with higher torques and longer contact zones – which requires highest mechanical stability. Even the smallest circular errors affect the quality of the workpiece. Therefore, the spindle is decisive for whether shape and position tolerances are observed – or not.

Our external grinding spindles – carefully designed for your challenge

In the field of external grinding, Steinmetz grinding technology offers various solutions that are precisely tailored to industrial requirements – from the individual component to the modular grinding system.

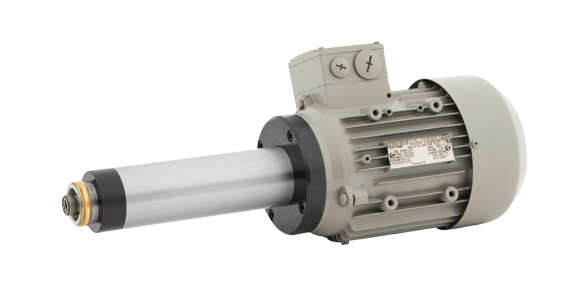

Our Motor spindles Drive and spindle unite in a compact, powerful unit – ideal for series processes, high torques and tight installation spaces. Through integrated water cooling and grease duration lubrication, they achieve a long service life with minimal maintenance effort.

With smooth tool holder

For classic grinding applications with reliable tool tension.

- Speed: up to 3,000 min-1

- Power: up to 5.5 kW

- stiffness radial: up to 310.2 N/μm

- stiffness axial: up to 155.1 N/μm

- Lubrication: grease duration lubrication

With HSK recording

Perfect for automated systems – short setup times, high change accuracy.

- HSK-C40 to C63

- Speed: up to 3,000 min-1

- stiffness radial: up to 421.8 N/μm

- stiffness axial: up to 254.3 N/μm

- Water cooling standard

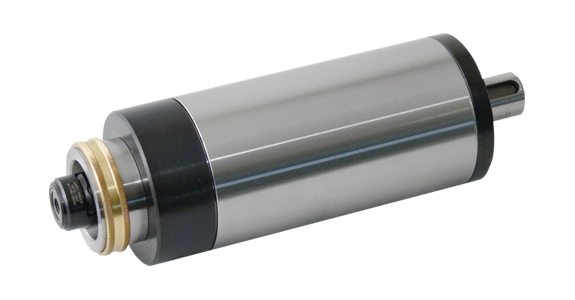

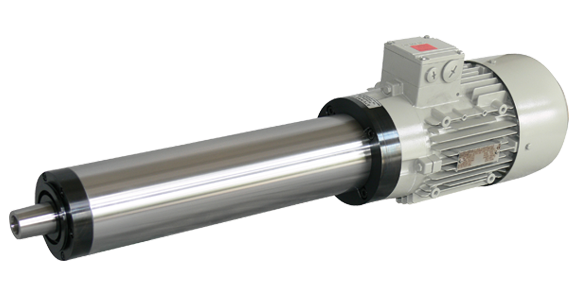

Our Belt-driven grinding spindles offer high speeds, reliable power transmission and flexible installation options – ideal for classic grinding machines and modern production cells. They are low-maintenance thanks to fat burning and available in numerous designs.

With smooth tool holder

Power-locking connection, high concentricity accuracy and robust design for external machining.

- Speed: up to 20,000 RPM

- Ø32–200mm, different lengths available

- Lubrication: grease duration lubrication or oil air lubrication for high speeds

With HSK recording

Quick change, high precision – ideal for automated processes.

- Speed: up to 20,000 min-1

- HSK-C40 to HSK-C100

Special productions

Not every grinding task can be solved with a standard spindle. For this reason, we also manufacture individual special designs at Steinmetz grinding technology – precisely adapted to your machine, workpiece and process conditions. Whether compact installation space, special tool mount or extreme loading requirements: Our custom designs show what is technically possible.

Technical overview

| Characteristics | MSP100X400F/006 (round table) | Spindle unit for optical lenses | Motor spindle for glass screens | SP46X100F/002 ( rims) | SP114,3×317,5 |

| Ø sleeve | 100 mm | 60 mm | 120 mm | 46 mm | 114.3 mm |

| Length | 400 mm | 160 mm | 400 mm | 100 mm | 317,5 mm |

| Record | cone Ø 35, 1:10 | Clamp 314 A (W10) | Cylindrical (pot disc) | cone Ø 24, 3,5:12 | cone Ø 41,275, 7:24 |

| Lubrication | Fat duration lubrication | Fat duration lubrication | Fat duration lubrication | Fat duration lubrication | Fat duration lubrication |

| Rotational direction | Right-left run | Right-left run | Right-left run | Right-left run | Right-left run |

| Max. Speed | 6,000 min-1 | 6,000 min-1 | 3,000 min-1 | 22.000 min-1 | 11.000 min-1 |

Product advantages of our external grinding spindles

Precision that is detectable

Our spindles offer a guaranteed concentricity of less than 2 μm. This means that even with sensitive surfaces or complex outer contours, the dimensional accuracy remains stable – from the first to the thousandth workpiece.

Constant power even under load

We rely on prestressed systems with high stiffness – both axially and radially. This keeps the spindle quiet and precise even at high pre-strains, long machining times or critical materials.

Low maintenance – with maximum service life

Thanks to our fat burning, regular maintenance is eliminated. No standstills occur due to oil change or relubrication. This reduces your operating costs and minimizes the risk of lubricant entry into the processing zone.

Custom fit

No matter what Retrofit or new installation – each spindle is manufactured exactly for your machine construction. Connection dimensions, flange shapes, tool mount: Everything is individually adjusted so that you do not have to rebuild – but can simply start.

How to benefit

- Reduced Committee: Low circular deviation means: less tolerance injuries, less rejection, less rework.

- Production safety: Our spindles are designed for continuous operation – thermally stable and mechanically loadable. This significantly reduces downtime.

- Short start-up phases: High repeatability ensures that processes run more stablely – ideal for series production.

- Real flexibility: You need a spindle with special mount, unusual dimensions or specific connection? We deliver single pieces with series-ready – on request also in 5 days.

Typical applications of our spindles

Our external grinding spindles prove themselves wherever precision, process reliability and adaptability are required:

- Tool and mold construction: For complex outer contours and high shape accuracy – even in demanding materials.

- Automotive and aviation industry: For grinding safety-critical components with close tolerance – reliable and reliable in series use.

- Medical technology: For the precise processing of sensitive materials – free of burrs, dimensional, repeatable.

- Mechanical Engineering & Retrofit: Ideal for retrofitting or in special machine construction – precisely adaptable to existing installation spaces and interfaces.

Our services – fast, solution-oriented, individual

Technical advice with clear evidence

You send us your drawing, we check the feasibility – and tell you what is realistic. No consolations, but clear recommendations based on decades of experience in spindle technology.

Construction & Manufacturing

No matter what Reconstruction, spare part or new project: We develop the spindle so that it fits exactly into your system. CAD interfaces, coordinated bearings and suitable sealing systems included.

Spindle repairs with original precision

Whether it’s your own products or other products: Repair grinding spindles all brands – fast, precise and with documented recovery of round running accuracy. If necessary also with spare parts from own production.

Spare parts supply in record time

We have many critical components in stock. Spare parts go out within 24–48 hours if necessary – so that your production does not stop.

Find the right outer grinding spindle now – or request individual solution!

You already have a drawing? Or do you need support in interpretation? Talk to us – we will contact us within 24 hours with a concrete solution. Without standard components, but exactly matched to your application.