Abrichttechnik von Steinmetz: Starts grinding quality

Contour, control, quality: This makes our dressing technique so special

Whether in tool grinding, serial production or retrofit projects – our dressing technology brings Wheels exactly in shape and keeps your processes stable. We offer a continuous system: Breaking spindles on Cycle breakers, receiving mandrels, Breakers to tailor-made devices and sensors for process monitoring.

All components are precisely matched, long-lastingly designed and manufactured according to application. This ensures permanently repeatable grinding results and reliable production – no matter how complex your application is.

dressing tasks for constant grinding power

To ensure that grinding processes remain permanently precise, grinding wheels must be regularly dressed. Our dressing technique takes on several crucial tasks – from the measurement correction to the restoration of the efficiency of cutting:

- Correct round and plan running: breaking processes eliminate unbalances and restore the exact geometry of the grinding wheel.

- Making dimensional accuracy: During the first profiling, the grinding wheel is brought exactly to the desired extent.

- Compensation of loss of form: The natural wear of the grinding contour is reliably compensated by dressing.

- Prevent lubrication: chip material and added grinding pores are removed – the grinding wheel remains open and efficient.

- Clear abrasive grains: The dressing technique produces new, sharp diamond grains on the surface – for consistently high cutting performance.

Our product portfolio in dressing technology

Our product portfolio in the field of dressing technology forms the entire chain around the precise dressing of grinding wheels. Each component – from the drive spindle to the Holder – is designed for specific use in your machine.

The combination of robust design, high precision and maximum adaptability makes our technology particularly efficient. Whether series production or single application: We deliver solutions that are technically convincing – and work reliably in everyday life.

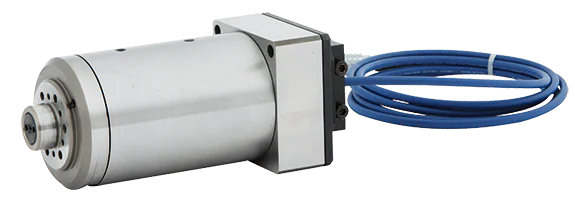

These spindles take over the drive for rotating diamond rollers during CNC-controlled alignment. They are available in various sizes, with air or water cooling as well as optional sensors (e.g. Dittel system). They are ideal for applications with high speeds, durable use and low tolerances.

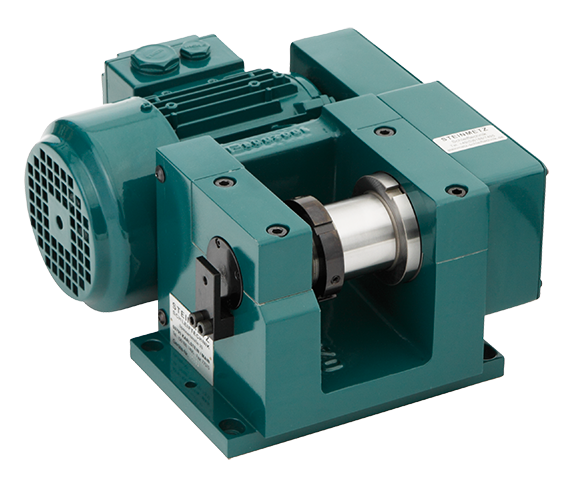

Our Diamond roller dressing equipment are designed for highest precision in use with diamond dressing rollers. The rigid, stress-free annealed GG25 base body ensures optimal damping. Depending on the design, the drive is electrically or hydraulic. With suitable receiving mandrels we achieve a maximum round and plan running of 2 μm. The roll exchange is uncomplicated, sensor technology can optionally be integrated.

For the safe hold of the diamond rolls in the dressing process. Our receiving mandrels guarantee the highest concentricity and are designed precisely for the respective roller geometry. Optionally available with individual lengths, clamping systems or fittings.

Cycle breakers

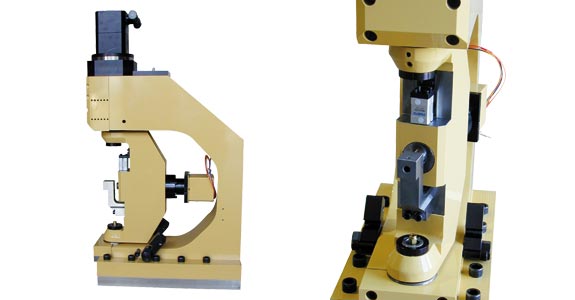

Our Cycle breakers are designed for precise alignment of convex and concave radii on grinding wheels of different sizes. They are available as flying or double-sided versions and can be used with single-grain diamond depending on the design, or Dressing spindle with diamond shaped roller ikea. The swivel drive is optionally effected via direct-current transmission motor, three-phase servomotor with transmission or hydraulic. Thanks to free radial and axial bearing, we achieve transverse shape deviations of only ±1 μm – for highest profile accuracy and reproducibility.

Our Spindle holder provide maximum stability for the precise use of our Diamond roller dressing spindles. They consist of low-voltage annealed GG25 and have fine-machined fitting surfaces with a parallelity of 0.01 mm to the receiving bore. The half shells are cut off by 0.05 mm after they have been screwed out, so the spindle is securely clamped without loading the housing. Special shapes are also possible for exact installation in your machine.

Technology that fits: Benefits of our dressing solutions

Our dressing technology convinces with a well-thought combination of precision, stability and individual adaptation – developed for the highest demands in grinding technology:

- Robust construction: All components – from spindles to devices – are made of low-voltage glowed GG25 and designed for industrial continuous operation.

- Precise interfaces: Fine-machined clamping and bearing surfaces ensure precise assembly and highest repeatability.

- Adjustable to detail: designs, flanges, bearing concepts and interfaces we manufacture exactly according to your machine requirements – even from batch size 1.

- Sensor technology if required: On request, we integrate systems such as cutting detection for process control and quality assurance.

- Compact designs: Ideal for retrofit or machines with limited installation space – without compromises in performance or precision.

How our dressing technology pays off in your company

- High production accuracy: round running and plan running precisions below 2 μm ensure constant results, even with tight tolerances.

- Less Committee: Exact and repeatable dressing processes prevent dimensional deviations and significantly reduce rework.

- Longer service life: Due to timely and targeted alignment, the grinding wheel remains efficient – this extends the service life and reduces tool costs.

- Stable process planning: Precise alignment means uniform production – production processes become more predictable and delivery dates more reliable.

- Low maintenance costs: permanent assemblies, low-maintenance lubrication and quickly available spare parts reduce maintenance costs.

- Easy integration: Our systems are seamlessly integrated into existing machine concepts – without great adaptation effort.