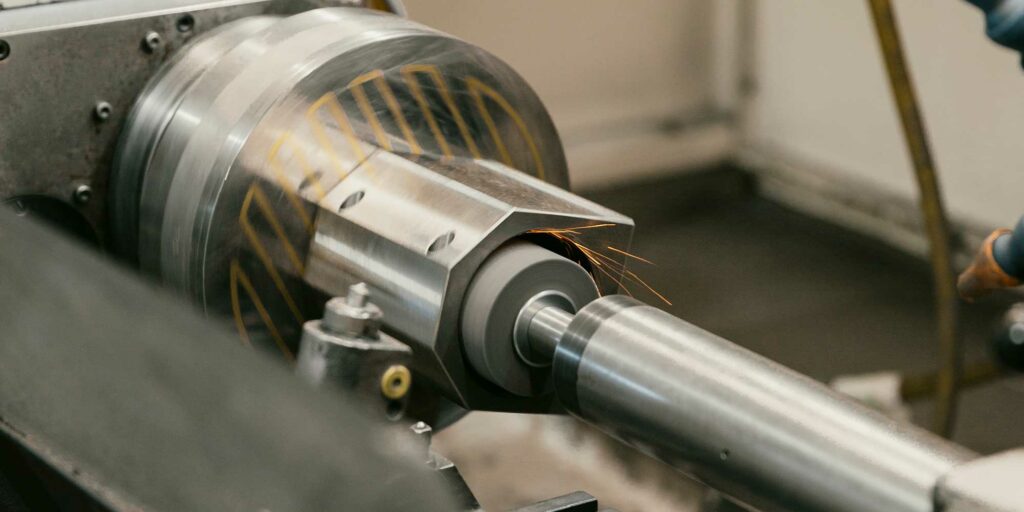

Breaking spindles: precision for perfect grinding results

Breaking spindles are essential for precise alignment of Wheels and ensure uniform grinding processes with highest accuracy. Depending on the application, we offer different types of construction with air or water cooling as well as different types of lubrication – for maximum service life and efficiency.

Our portfolio of dressing spindles

In Steinmetz grinding technology you get dressing spindles that are exactly matched to your application. For maximum grinding precision, long service life and reliable processes – from Compact spindle to tailor-made Special production.

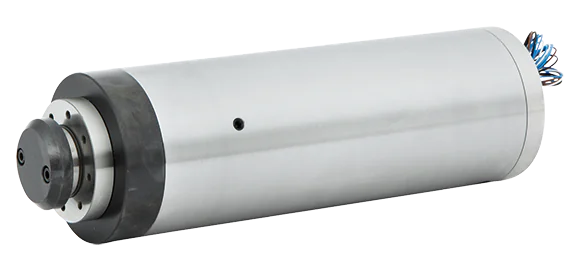

Compact dressing spindles (Ø 42–58 mm)

Typical features

- Outer diameter: 42–58 mm

- Speeds up to 28,400 min-1

- Performance: up to approx. 0.4 kW

- Lubrication: grease duration lubrication

- Cooling: usually without or air cooling

Typical series

- AS42x147F

- AS58x94F

- AS58x111

Areas of application

- Tool grinding in compact machines

- Retrofit solutions for lack of space

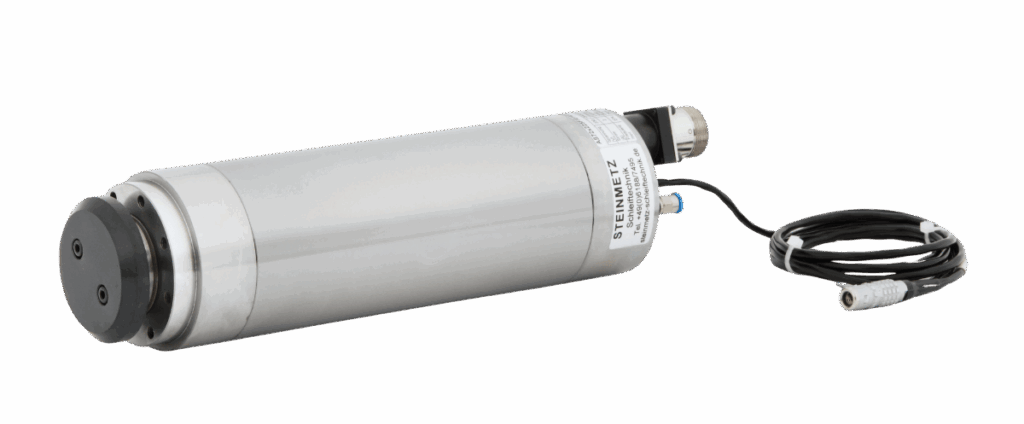

Medium standard spindles (Ø 72–100 mm)

Typical features

- Outer diameter: 72–100 mm

- Speeds: up to 19,000 min-1

- Power: up to 1.2 kW

- Cooling: air or oil

- Voltages: 220–350 V

- Cutting detection via Dittel system possible

Typical series

- AS72x205F

- AS72x220F

- AS80x225F

- AS90x250F

- AS100x300F

Areas of application

- Internal and external circular grinding

- Form and profile grinding

- Serial and single parts production

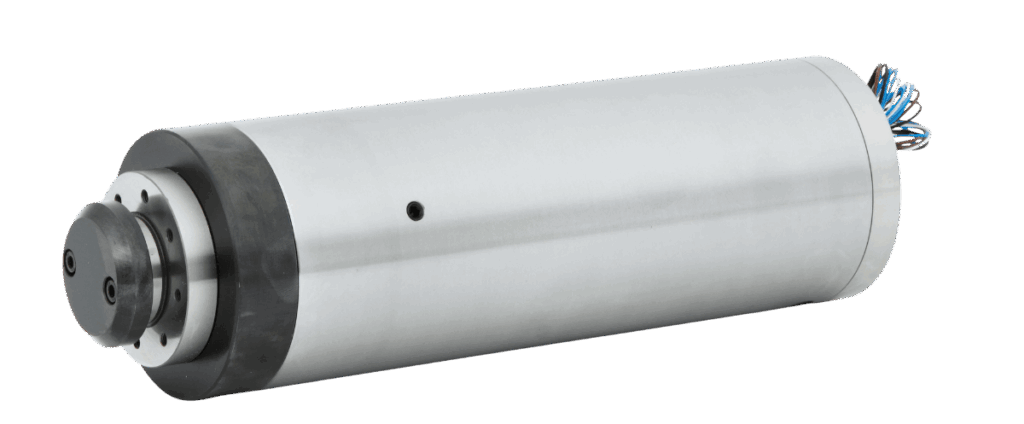

High-performance dressing spindles (Ø 120 mm)

Typical features

- Outer diameter: 120 mm

- Speeds up to 9.720 min-1

- Continuous power up to 3.5 kW

- Lubrication: grease duration lubrication

- Cooling: air or water cooling

Typical series

- AS120x320F

- AS120x270F

Areas of application

- grinding centers with high ablation

- Serial production in hard materials

- Applications with continuous operation and closest tolerances

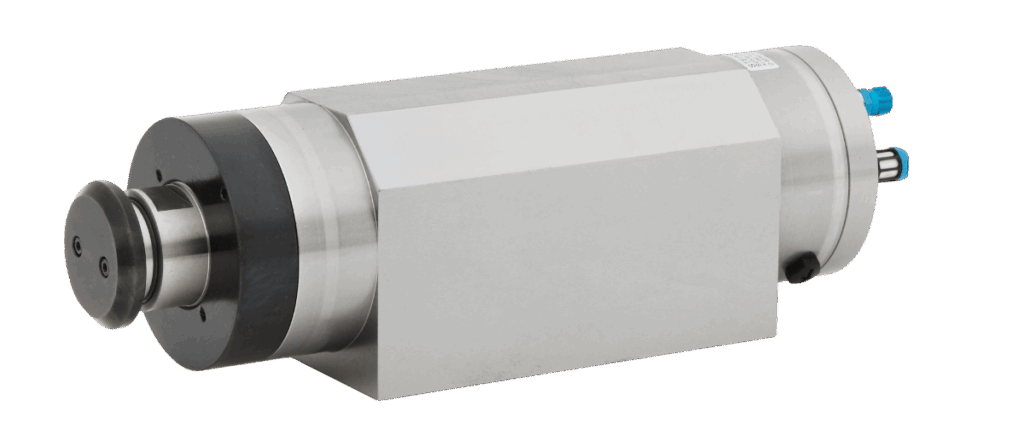

custom productions according to customer request

Possible options

- Individual dimensions, sleeve lengths or flanges

- Special connections for cooling and blocking air

- Drive via pulley or directly

- Design with or without sensor technology

- Production already from small quantities

Typical examples

- spindle 139118: Ø 110 mm, 350 mm sleeve length, belt drive

- AS63x10F/001: Belt drive, Labyrinthab seal

- AS63x10Ö/001: Oil fog lubrication, Ø 63 mm

Areas of application

- Machine modernization (retrofit)

- Special machinery

- Spare parts production of spindle types no longer available

Additional features for your dressing spindles

Belt drive available

In certain spindle types, the drive does not take place via an integrated motor, but via an external Belt. This option is especially relevant for custom productions and offers maximum flexibility for installation in special machines.

- Available at: Special productions

- Advantages: space-saving installation, independent drive design

Cutting detection / sensor system integrated

For automated processes, we offer spindles with integrated sensor technology (e.g. Dittel). The cut detection increases process reliability, allows reproducible grinding results and prevents tool wear.

- Optional for: compact, standard and high-performance spindles

- Systems: Dittel-Sensorik (incl. Micro-M sensor, transmitter, receiver)

- Benefits: Process control, Safety, Quality assurance

Your advantages of Steinmetz grinding technology

✔ Quick availability – offers in 24h, spare parts in 24-48h

✔ Highest quality – dressing spindles with accuracy below 2 μm

✔ Flexibility – Also custom productions in small quantities

✔ Competent service – repairs, spare parts and individual advice