Breaker – The key to perfect grinding profiles

More than just dressing: this can be a modern dressing device

A dressing device is the precise tool for perfect grinding results: It shapes and conditions your grinding wheels so that every contour, cutting edge and edge sits exactly where it is to be. The effect? Constant quality and a controlled, repeatable grinding process, even with closest tolerances and high timing.

At Steinmetz, we deliver dressing devices that are precisely tailored to your application – as a single module or in a perfectly matched system with Spindles, Holders and receiving mandrels.

Our dressing equipment at a glance

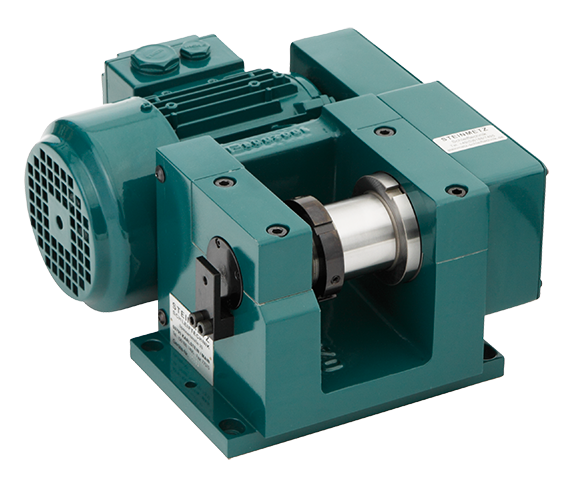

Diamond roller dressing equipment

Our Diamond roller dressing equipment were developed for use on flat, outer round, inner round and guide track grinding machines. They offer a particularly stiff construction with very good damping properties, based on a base body made of stress-free annealed GG25.

Depending on the design, the drive takes place electrically or hydraulically. Combined with matching diamond roller pick-up mandrels, the devices allow a maximum round and plan running of 2 μm – ideal for reproducible grinding quality and fast roller exchange.

Cycle breakers

Our Cycle breakers are designed for precise alignment of convex and concave radii on grinding wheels of different sizes.

They are available as variants supported on both sides and can be fitted with single-grain diamond or dressing spindle with diamond forming roller, depending on the design. The swivel drive is optionally effected via direct-current transmission motor, three-phase servomotor with transmission or hydraulic.

Thanks to free radial and axial bearing, we achieve transverse shape deviations of only ±1 μm – for highest profile accuracy and reproducibility.

Technique that shows the effect: this is in the dressing process

A precise grinding pattern begins with the correct dressing process. Our dressing devices consist of a finely tuned combination of dressing spindle, Holder and optional guide device.

The spindle rotates the dressing tool, for example a diamond roller, and guides it with exactly defined contact pressure against the grinding wheel.

The abrasive is specifically shaped, roughened and freed from material residues – for clear contours and a uniform grinding behavior. This process is not only the basis for dimensional accuracy, but also crucial for the service life of your tools.

Strong in application: the advantages of our dressing equipment

Highest precision

Maintenance-free continuous operation

Long service life

Individual adjustment

Easy integration

Cost efficiency in operation

dressing device in application

Whether single-part machining or highly automated series production – our dressing devices perform reliable work wherever precision and process reliability are crucial. Different industries rely on our technology because it is not only highly accurate, but also durable and flexible to integrate:

- Tool and mold construction: For the precise alignment of complex contours in tools and molds where exact geometries and repeatability are important.

- Automotive and aviation industry: In series productions with high cycle numbers, our devices ensure constant grinding quality and minimise tolerance deviations – even with continuous load.

- Medical technology: Precision on micrometer level is crucial especially for fine-mechanical components. Our dressing devices allow smooth, precise surfaces without rework.

- machining and wage production: Thanks to its flexibility and reliability, our devices are ideal for companies with frequently changing orders – with consistently high quality.

- Mechanical engineering: In new machines or retrofit projects, our dressing devices ensure efficient and process-stable grinding processes with different workpiece sizes and materials.